Email: conny@topshakerscreen.comTel: +86 13132436786

Home NEWS Industry-news shaker screen, classification of shale s…

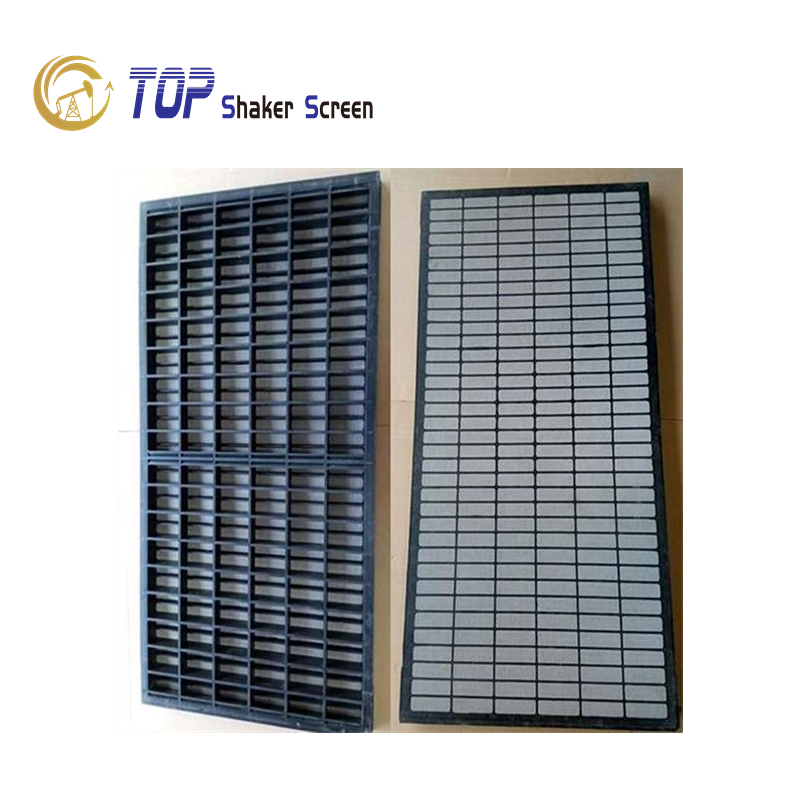

Top distinguish screen patterns, there are many references or methods. Firstly, we can judge it according to appearance. Such as flat panels and corrugated panels. Sometimes, we’ll call it flat-panel “PWP”), and we’ll call panel with corrugation wave “PMD” It’s an abbreviation of “pyramid”.

Then, we divide shaker screen panels as per the installation way or compression way. There are screens installed by ten sioning hook at the side, we call them hook strap screens; there are screens compressed by wedge blocks we call them wedged panels; there are screen panels pressed or pushed by atmospheric, most of such panels are framed panels; there are screens pushed by side tools and fixed by a pin on notch; there are also screens pressed by hydraulic pressure, such screens can be hook strap or framed; furthermore, there are screens pulled by hook and the ten sioning unit, too.

Composite framed screen

Shaker screens pattern

Thirdly, we can find there are screens with frames, without back metal support plate, without plastic or composite support. That means different materials and procedures.

Fourthly, many people don’t know there are screens made of different raw materials. Such as stainless steel wire mesh screen, polyurethane screen, steel wedge screen panel, 16Mn screen panels, and so on

Fifthly, there are composite framed screens and metal-framed screens. Among these screens, there are flat panels and corrugated panels.

Different features of different patterns of screen

We have talked about differences among the above patterns of the screen. What are the different features then? Considering the flat panel and corrugated panel, the difference is the effective area of the screen. Yes, the panels with waves hold a larger area, so we can say their flow rate or efficiency is higher.

Compared shaker screen with each other on installation way, we’ll find users prefer the fast and easy way. Among these installation ways, some hook strap screens are more popular, while some screen panels pressed by pressure or hydraulic are preferred, too. However, considering the consumables and wearing parts cost, a wedge blocked panel is a more economical choice.

Screen panels with waves

The material of screen frame difference leads to different production procedures and techniques. A composite frame screen provides a longer shelf life and service life. For some models of the screen, composite frames are lighter than metal frame panels. Composite framed screens hold a better performance on rust-resistant, however, steel-framed ones hold a better performance on high-temperature resistance.

Material of screen cloth defines screen application and performance. PU framed screens can be used in sludge treatment or civil construction separation but with lower viscosity, PU hook strap (flexible) screens can be used in the mineral industry. S.S screens are suitable for oil drilling mud process, mud waste management and so on. While the 16Mn screens are mostly used in stone sieving or other jobs that request higher abrasion resistance.

If we take the screen cloth configuration in consideration, there are oblong apertures and square apertures. Some panels are holding all layers with square hole wire mesh, while some panels are holding one layer or two layers of rectangular hole mesh. The difference are the conductance or the penetration efficiency and the exact separation point.

What patterns of shaker screens are available at Aipu?

All above-listed shaker screen patterns are available at Aipu. The hook strap screens, the wedge blocked shaker screen, the flat or corrugated panel, the composite or metal-framed screens, the polyurethane or the S.S wedge wire screen panels, and so on.

For more information contact us:

For more technical questions, please contact us

Name: Conny LI

Mobile:+86 13132436786

Whatsapp:https://wa.link/ond5vi

Email: conny@topshakerscreen.com

Add:Units 1-3, Block A, Jinyue Industrial Zone, Huafu Street, Raoyang, Anping County, Hebei Province, China