Email: conny@topshakerscreen.comTel: +86 13132436786

Home PRODUCTS Substitute Shale Shaker Screen for BRANDT TOP: Substitute Flat Screens for Brandt

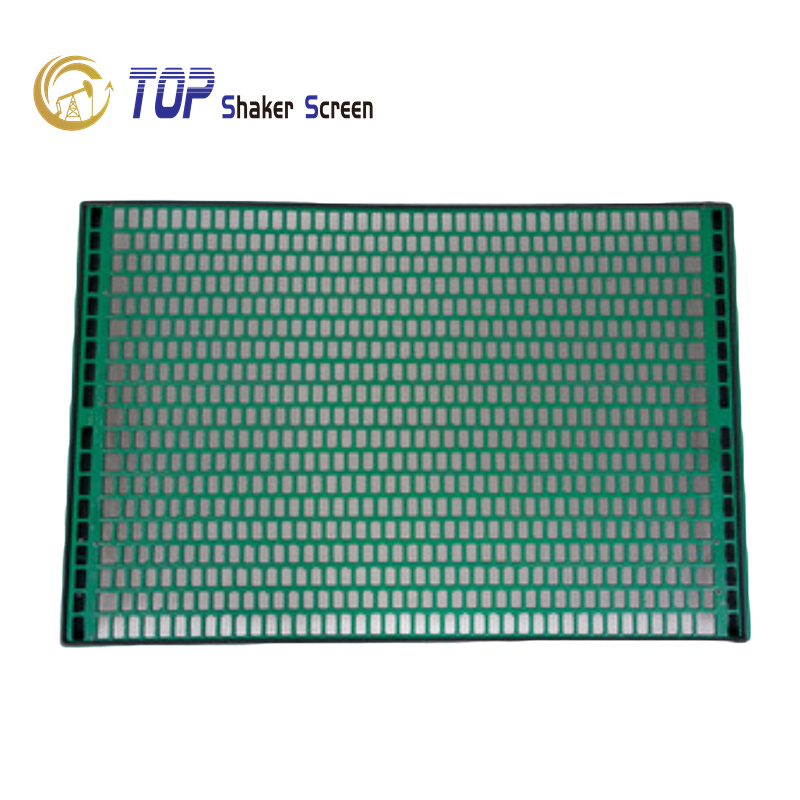

Brandt BLBRANDT VSM 300 Primary Shaker Screen Replacement are constructed with two or three layers of 304 or 316 stainless steel wire mesh cloth, and then combined together with a steel backing plate. This

type of shaker screen is produced for the replacement sshaker creen for Brandt BLT-50/LCM-2D (bottom basket) shale shaker screen.

|

Item |

API RP 13C Designation |

Mesh Type |

Conductance number |

D100 Separation(μm) |

Layer no. |

Non-blank area (sq.ft) |

|

1 |

API 325 |

XR |

0.39 |

44 |

1/2/3 |

4.6 |

|

2 |

API 270 |

XR |

0.67 |

57 |

1/2/3 |

4.6 |

|

3 |

API 230 |

XR |

0.71 |

68 |

1/2/3 |

4.6 |

|

4 |

API 200 |

XR |

1.32 |

73 |

1/2/3 |

4.6 |

|

5 |

API 170 |

XR |

1.34 |

83 |

1/2/3 |

4.6 |

|

7 |

API 140 |

XR |

1.89 |

101 |

1/2/3 |

4.6 |

|

8 |

API 120 |

XR |

1.89 |

134 |

1/2/3 |

4.6 |

|

9 |

API 100 |

XR |

2.66 |

164 |

1/2/3 |

4.6 |

|

10 |

API 80 |

XR |

2.76 |

193 |

1/2/3 |

4.6 |

|

11 |

API 70 |

XR |

3.33 |

203 |

1/2/3 |

4.6 |

|

12 |

API 60 |

XR |

4.10 |

268 |

1/2/3 |

4.6 |

|

13 |

API 50 |

XR |

5.17 |

285 |

1/2/3 |

4.6 |

|

14 |

API 40 |

XR |

8.64 |

439 |

1/2/3 |

4.6 |

|

15 |

API 35 |

XR |

9.69 |

538 |

1/2/3 |

4.6 |

|

16 |

API 20 |

XR |

10.88 |

809 |

1/2/3 |

4.6 |

Categories:Shaker Screen.

[1]Derrick and FLC and Pyramid are trade marks of Derrick Corporation

[2]Brandt and NOV are trade marks of National Oilwell Varco

[3]MI-Swaco and Mongoose are trade marks of Schlumberge

Name: Conny LI

Mobile:+86 13132436786

Whatsapp:https://wa.link/ond5vi

Email: conny@topshakerscreen.com

Add:Units 1-3, Block A, Jinyue Industrial Zone, Huafu Street, Raoyang, Anping County, Hebei Province, China